Summary

New method for estimating the background pattern of image sensors at any operating temperature, based on laboratory measurements performed beforehand. Allows accurate correction of images in situations where sensor temperature cannot be controlled and mechanical shutters for in-situ calibration are not available. Simplifies camera operation while enabling size, weight and power optimizations.

Example: Vegetation moisture maps taken by space camera based on uncooled InGaAs technology.

| Intellectual Property | Patent granted in EP, JP, filed in US, CN and AR |

|---|---|

| Estado de desarrollo | TRL 9Validated in three space missions featuring uncooled SWIR cameras |

| Intended collaboration | Licensing or assignment |

| Contact | Anselmo Sosa Méndez Unidad de Apoyo a la Investigación y Transferencia ait [at] iac.es (ait[at]iac[dot]es) |

Market need

Image sensors produce background patterns that need to be corrected in every acquired image. These patterns depend on sensor temperature, among other parameters. Failing to correct them properly could result in images not meeting the required quality levels.

In some sensor technologies like InGaAs, the dependency with temperature is so strong that camera manufacturers have been forced to add temperature control systems to stabilize the temperature to some specific value(s), with the associated background patterns measured beforehand in factory or in the field with the help of mechanical shutters.

There are applications where controlling the temperature is not a feasible solution due to the limited amount of available power, mass and volume to devote to the temperature control system, specially when the ambient temperature can change rapidly.

Proposed solution

We propose an new method that allows obtaining high quality images by correcting the background patterns of image sensors at any operational temperature, thus removing the need of including temperature stabilization systems in cameras where such systems were mandatory.

Cameras integrating this method can benefit from a significant reduction of power, mass and volume, as well as from simplified operational requirements. This enables new applications in the aerospace, automotive and environmental monitoring markets, among others.

Competitive advantages

Accuracy | Correction performance is comparable to in-situ camera characterization. |

Simplicity | The algorithm can easily run in an embedded system, such as the camera itself. |

Flexibility | Works with any type of sensor, as it does not assume any specific pixel model. |

Further examples

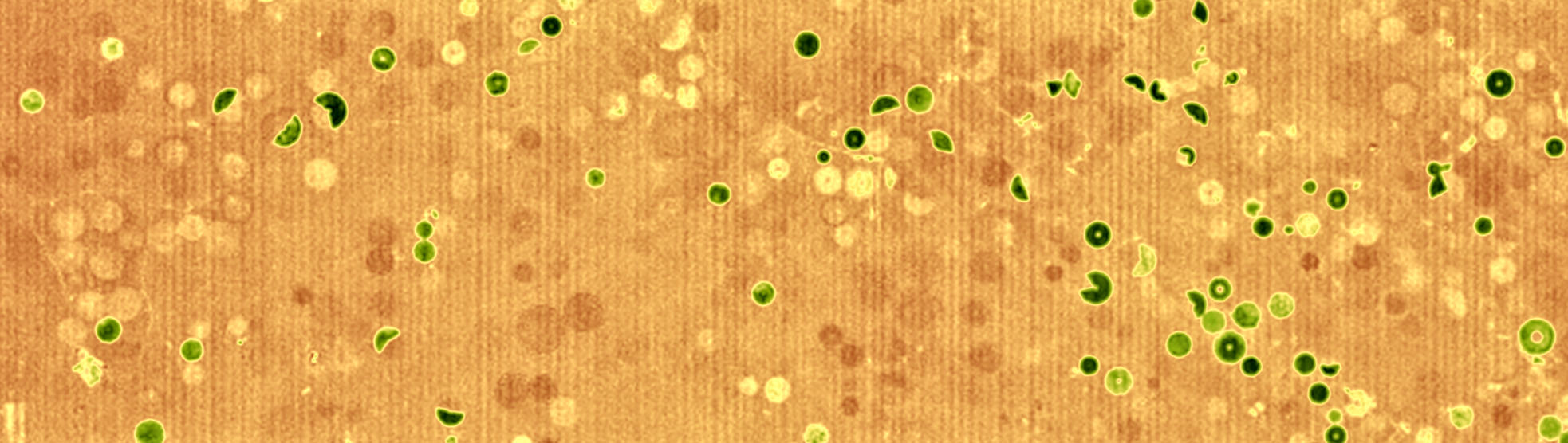

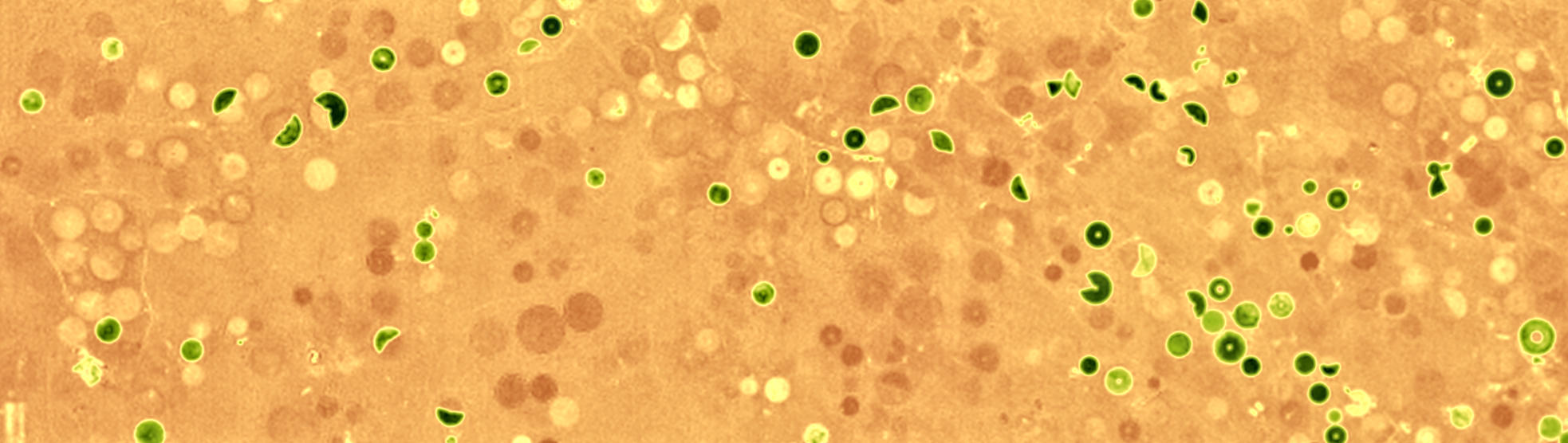

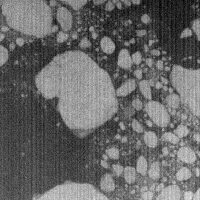

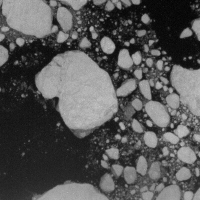

The images below have been taken by the DRAGO-2 camera onboard the ALISIO-1 satellite, based on uncooled InGaAs technology. With the proposed method, images can be properly corrected regardless the acquisition configuration and operating temperature, revealing features that would otherwise be hidden by sensor noise.

Greenland coast

Glacier ice and snow are challenging to image due to their low reflectivities at these wavelengths.

Euphrates River

Exposure time was set to simulate the small amount of light that high-resolution satellites can typically gather.

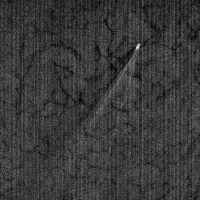

Mediterranean Sea

Proper correction of maritime images reveals further details about water texture and ship water trails.